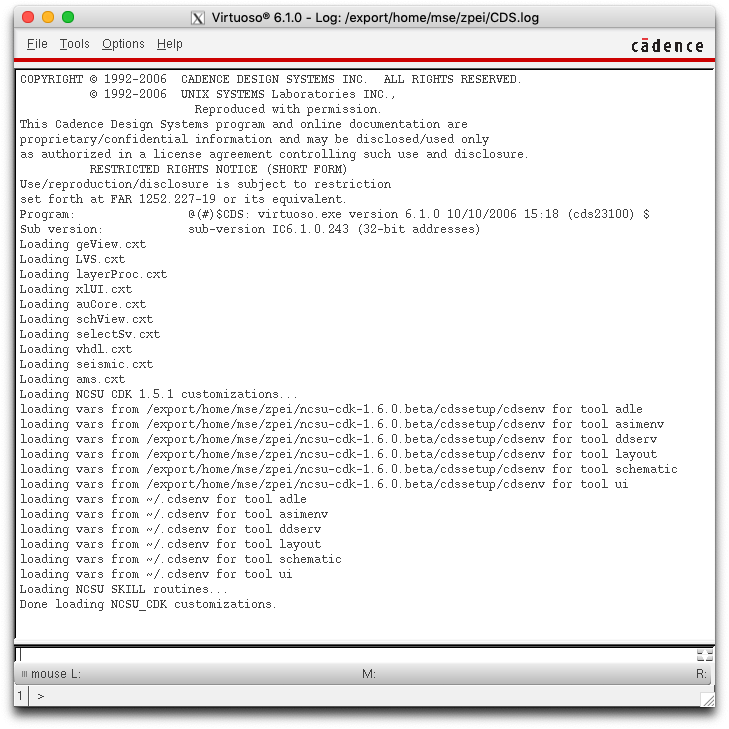

Cadence Virtuoso

I used Cadence® Virtuoso® to design layout for Electromigration (EM) Test Pad for tape-out with Harris Corporation and ICAMR in Fall 2016, partner was Novati Technologies, Inc. who I submitted GDSII to.

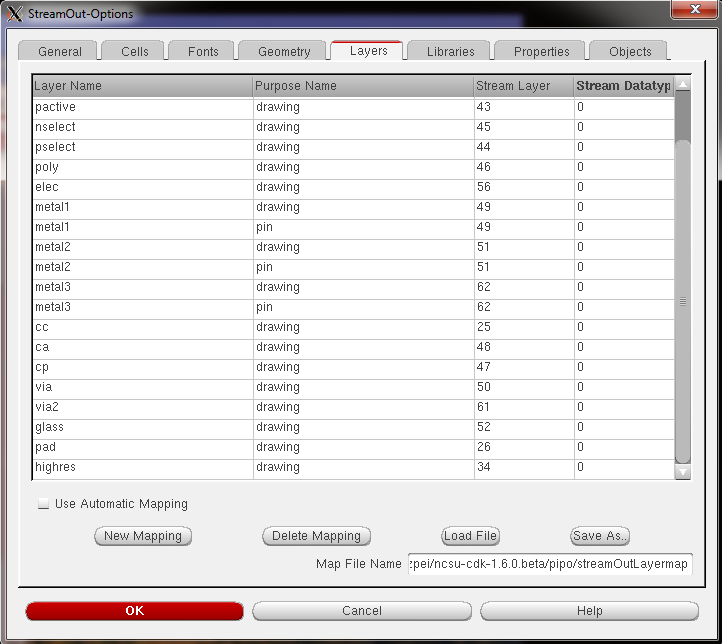

Map file was from MOSIS: https://www.eda.ncsu.edu/wiki/MOSIS_Layers.

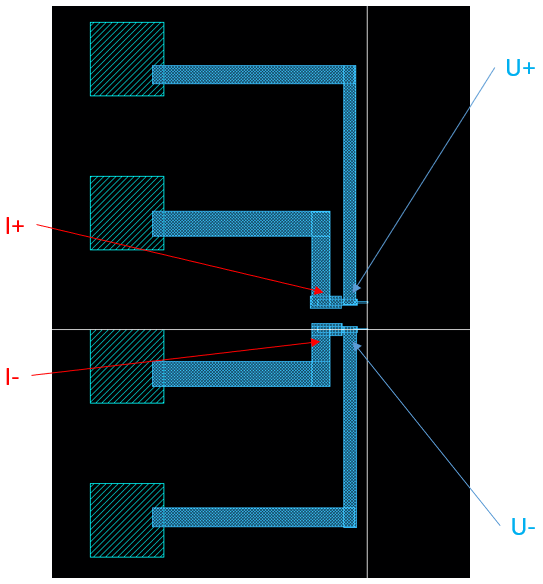

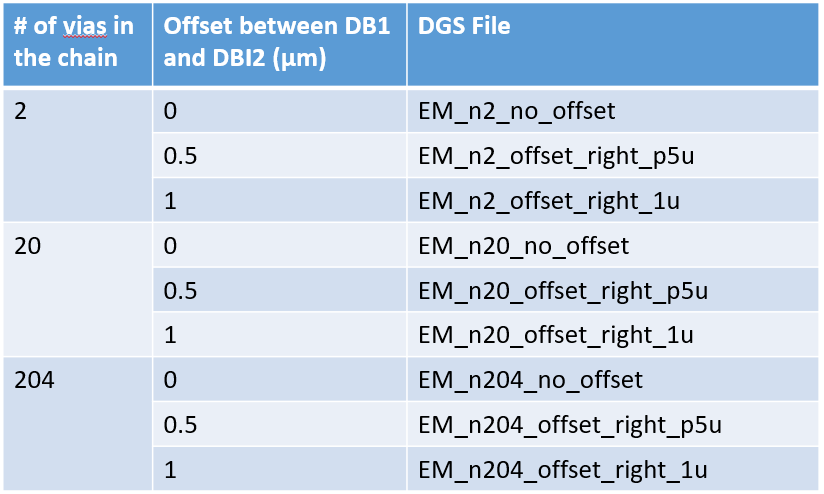

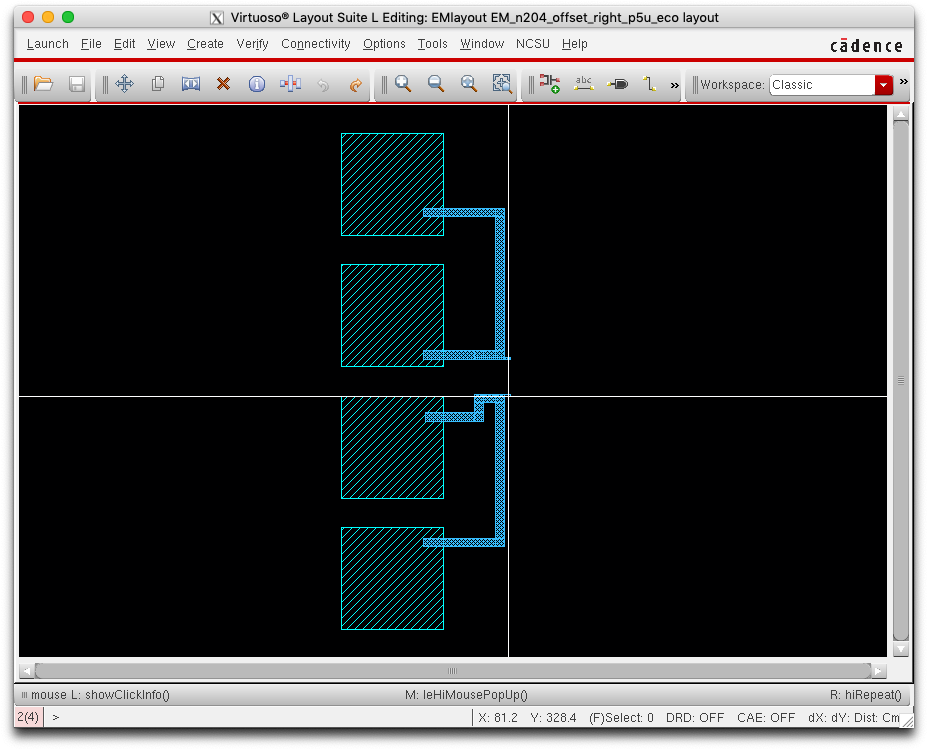

The test pad size: 120um x 120 um. Pitch: 250um, which means 130um spacing between 2 test pads, with maligned vias, or different numbers of links, or different trace widths.

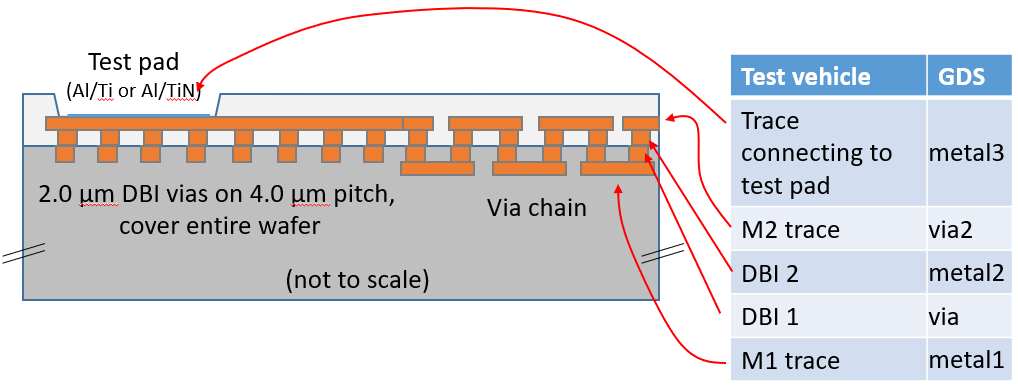

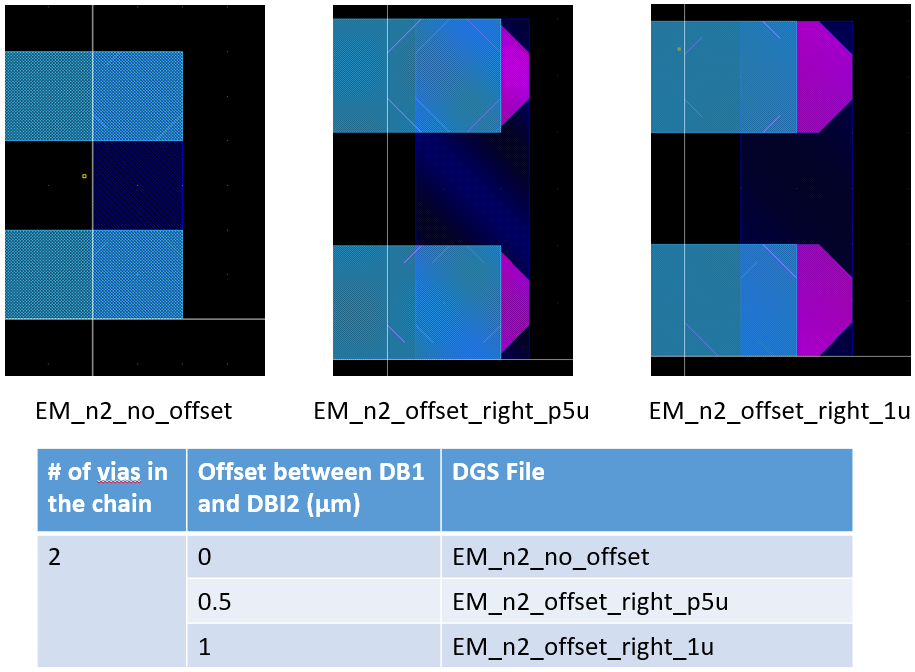

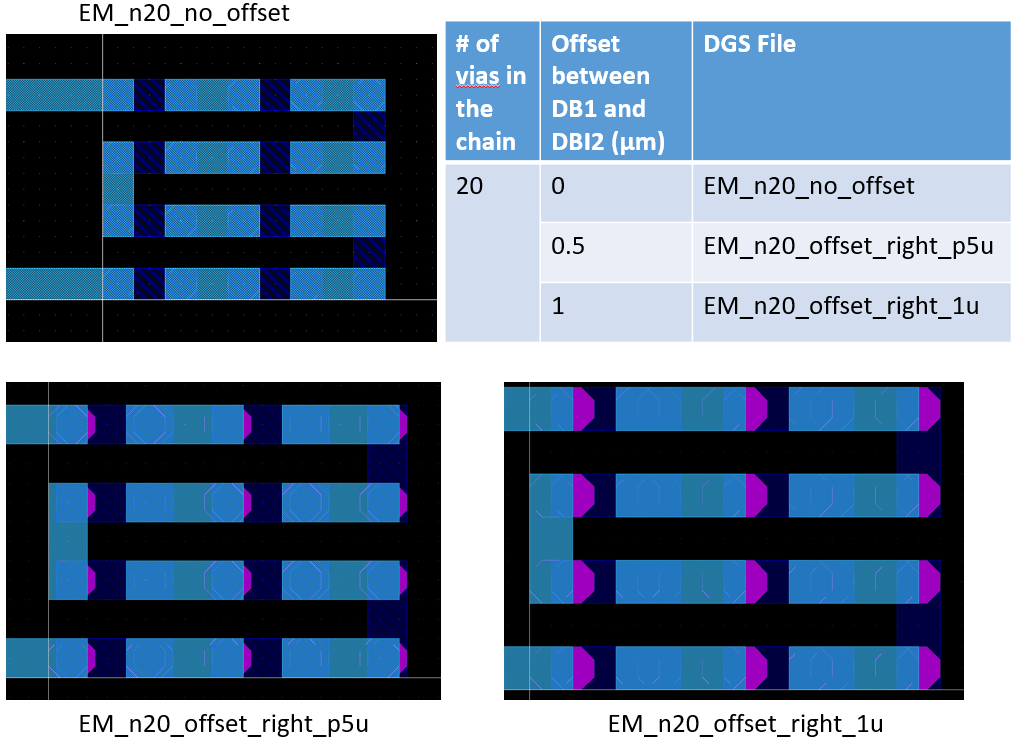

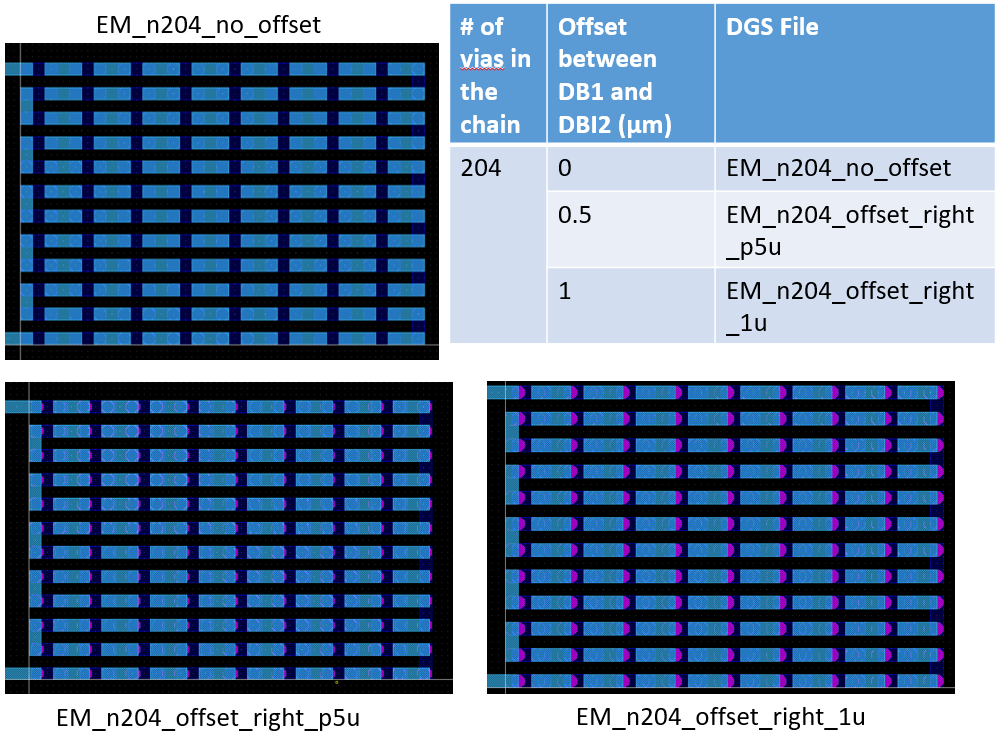

The stack-up was M1, DBI1, DBI2, M2. DBI1 and DBI2 are nominally identical, unless the designer wanted to intentionally misalign them.

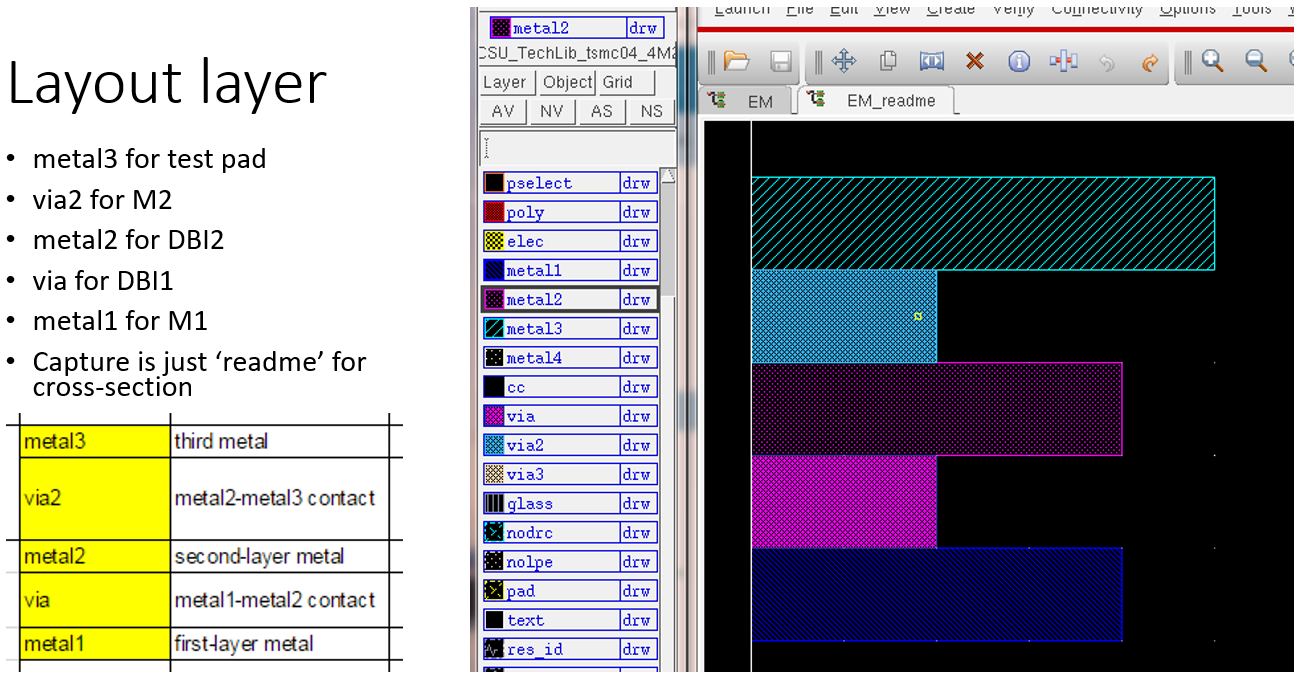

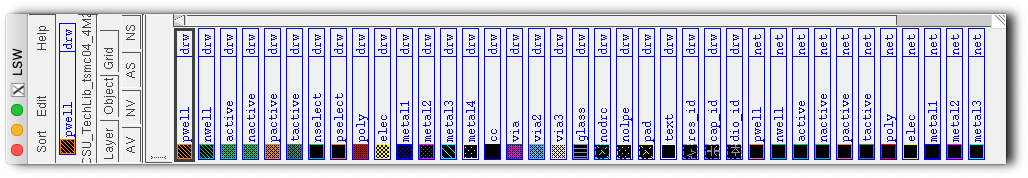

Virtuoso layout layers: metal 1 was the first-layer metal, via was metal1-metal2 contact, metal 2 was the second-layer metal, via2 was the metal2-metal3 contact, metal3 was the third metal. For EM Test Pad foundry, metal1 was for M1, via was for DBI1, metal2 was for DBI2, via 2 was for M2, and metal3 was for test pad.

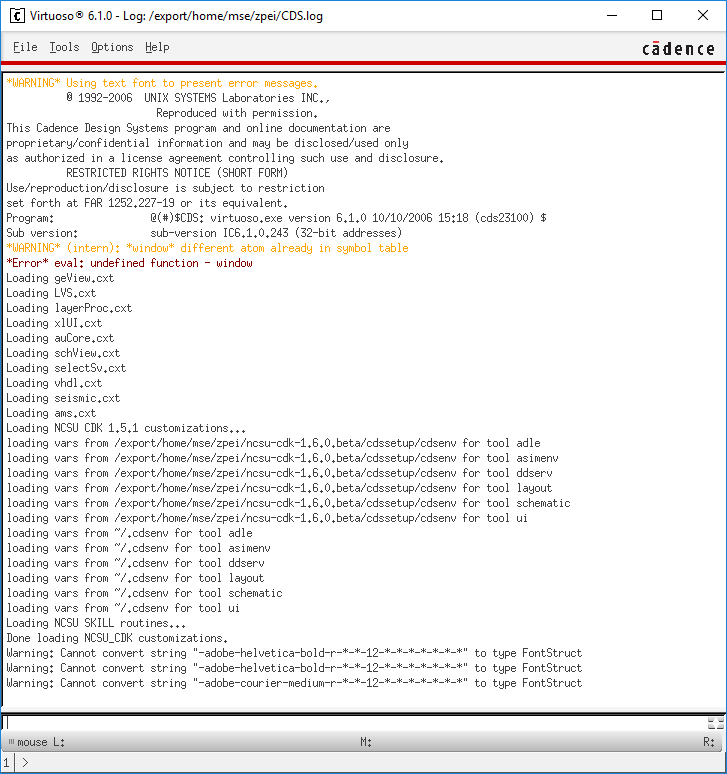

Cadence Products Run on a variety of UNIX- and PC-based Systems

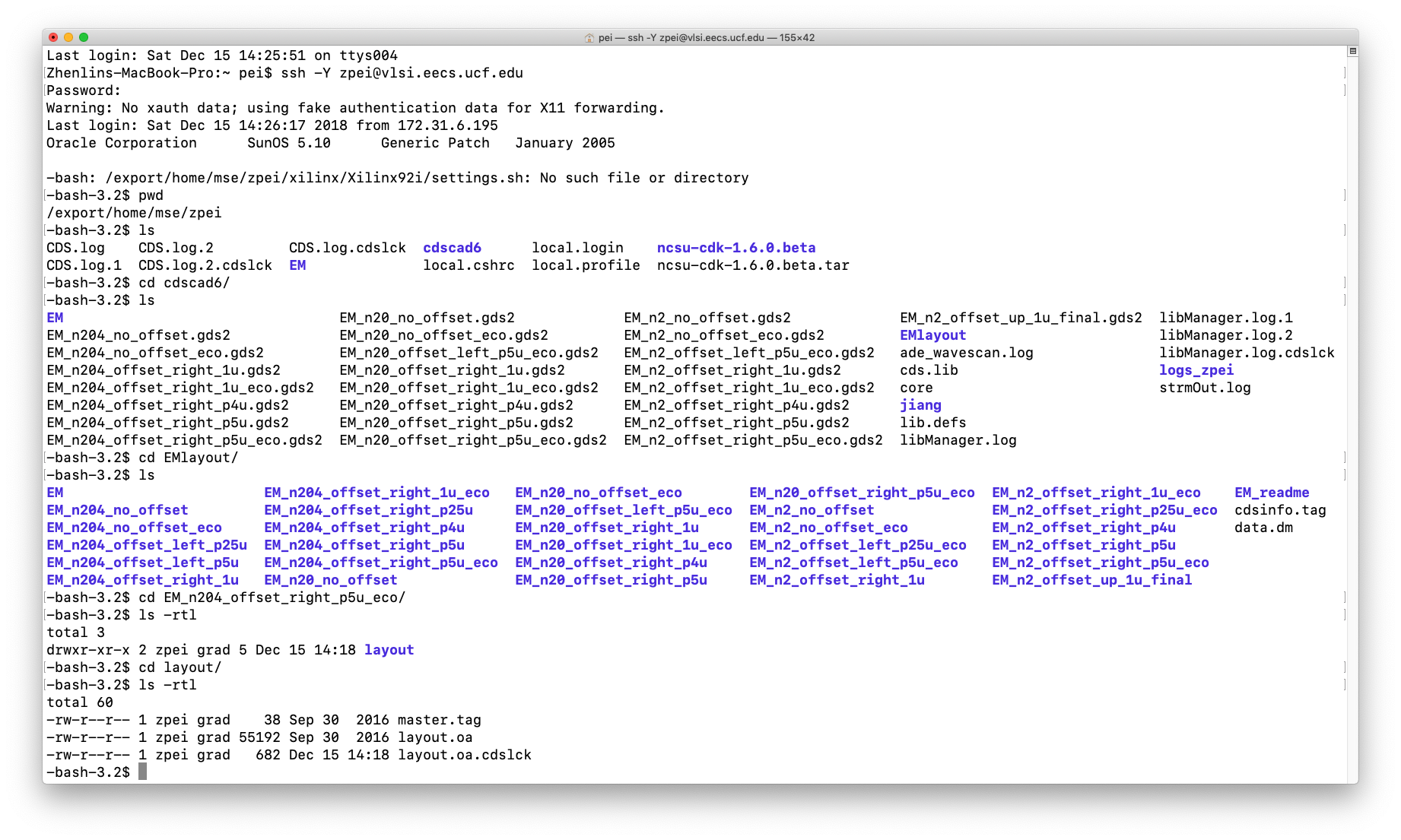

Remote access to the Linux Servers

Macintosh User

Running Cadence Virtuoso®

icfb

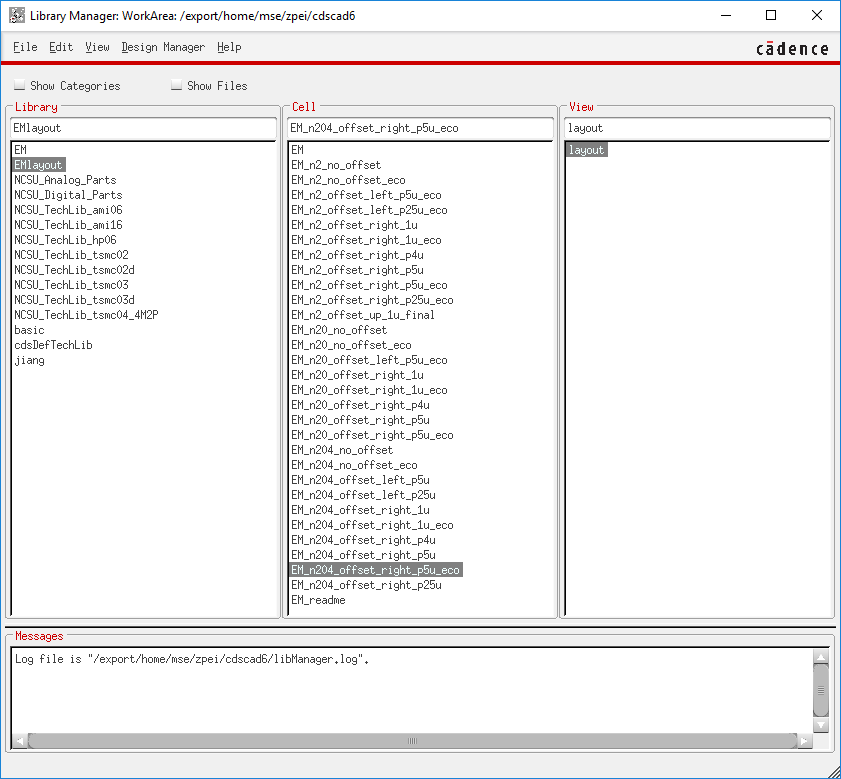

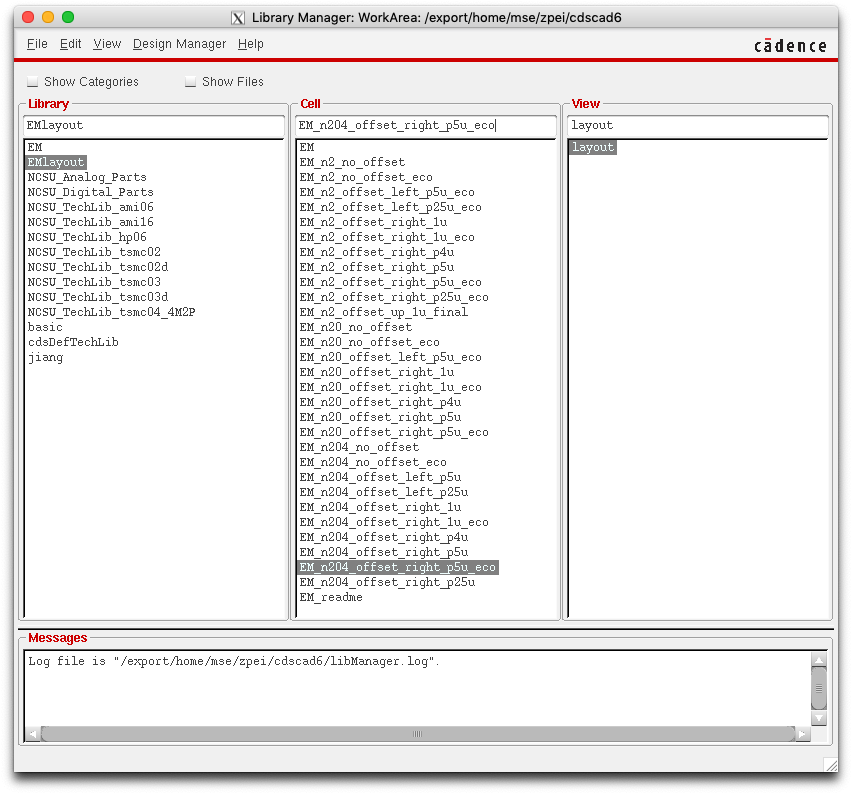

Library Manager

WorkArea: /export/home/mse/zpei/cdscad6

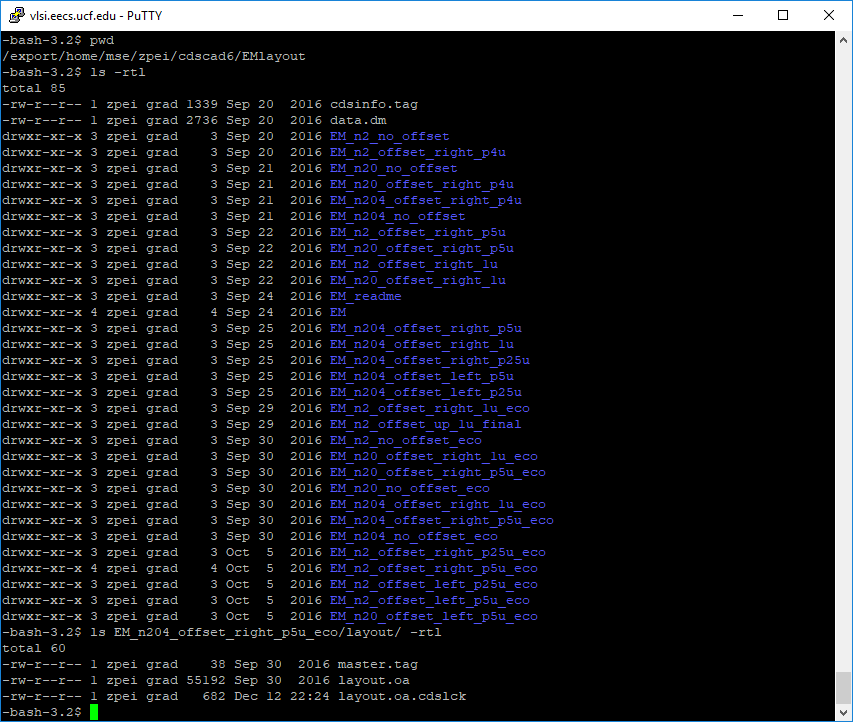

-bash-3.2$ pwd

/export/home/mse/zpei/cdscad6/EMlayout

-bash-3.2$ ls -rtl

total 85

-rw-r–r– 1 zpei grad 1339 Sep 20 2016 cdsinfo.tag

-rw-r–r– 1 zpei grad 2736 Sep 20 2016 data.dm

drwxr-xr-x 3 zpei grad 3 Sep 20 2016 EM_n2_no_offset

drwxr-xr-x 3 zpei grad 3 Sep 20 2016 EM_n2_offset_right_p4u

drwxr-xr-x 3 zpei grad 3 Sep 21 2016 EM_n20_no_offset

drwxr-xr-x 3 zpei grad 3 Sep 21 2016 EM_n20_offset_right_p4u

drwxr-xr-x 3 zpei grad 3 Sep 21 2016 EM_n204_offset_right_p4u

drwxr-xr-x 3 zpei grad 3 Sep 21 2016 EM_n204_no_offset

drwxr-xr-x 3 zpei grad 3 Sep 22 2016 EM_n2_offset_right_p5u

drwxr-xr-x 3 zpei grad 3 Sep 22 2016 EM_n20_offset_right_p5u

drwxr-xr-x 3 zpei grad 3 Sep 22 2016 EM_n2_offset_right_1u

drwxr-xr-x 3 zpei grad 3 Sep 22 2016 EM_n20_offset_right_1u

drwxr-xr-x 3 zpei grad 3 Sep 24 2016 EM_readme

drwxr-xr-x 4 zpei grad 4 Sep 24 2016 EM

drwxr-xr-x 3 zpei grad 3 Sep 25 2016 EM_n204_offset_right_p5u

drwxr-xr-x 3 zpei grad 3 Sep 25 2016 EM_n204_offset_right_1u

drwxr-xr-x 3 zpei grad 3 Sep 25 2016 EM_n204_offset_right_p25u

drwxr-xr-x 3 zpei grad 3 Sep 25 2016 EM_n204_offset_left_p5u

drwxr-xr-x 3 zpei grad 3 Sep 25 2016 EM_n204_offset_left_p25u

drwxr-xr-x 3 zpei grad 3 Sep 29 2016 EM_n2_offset_right_1u_eco

drwxr-xr-x 3 zpei grad 3 Sep 29 2016 EM_n2_offset_up_1u_final

drwxr-xr-x 3 zpei grad 3 Sep 30 2016 EM_n2_no_offset_eco

drwxr-xr-x 3 zpei grad 3 Sep 30 2016 EM_n20_offset_right_1u_eco

drwxr-xr-x 3 zpei grad 3 Sep 30 2016 EM_n20_offset_right_p5u_eco

drwxr-xr-x 3 zpei grad 3 Sep 30 2016 EM_n20_no_offset_eco

drwxr-xr-x 3 zpei grad 3 Sep 30 2016 EM_n204_offset_right_1u_eco

drwxr-xr-x 3 zpei grad 3 Sep 30 2016 EM_n204_offset_right_p5u_eco

drwxr-xr-x 3 zpei grad 3 Sep 30 2016 EM_n204_no_offset_eco

drwxr-xr-x 3 zpei grad 3 Oct 5 2016 EM_n2_offset_right_p25u_eco

drwxr-xr-x 4 zpei grad 4 Oct 5 2016 EM_n2_offset_right_p5u_eco

drwxr-xr-x 3 zpei grad 3 Oct 5 2016 EM_n2_offset_left_p25u_eco

drwxr-xr-x 3 zpei grad 3 Oct 5 2016 EM_n2_offset_left_p5u_eco

drwxr-xr-x 3 zpei grad 3 Oct 5 2016 EM_n20_offset_left_p5u_eco

-bash-3.2$ ls EM_n204_offset_right_p5u_eco/layout/ -rtl

total 60

-rw-r–r– 1 zpei grad 38 Sep 30 2016 master.tag

-rw-r–r– 1 zpei grad 55192 Sep 30 2016 layout.oa

-rw-r–r– 1 zpei grad 682 Dec 12 22:24 layout.oa.cdslck

-bash-3.2$

Layout for Electromigration Test Pad

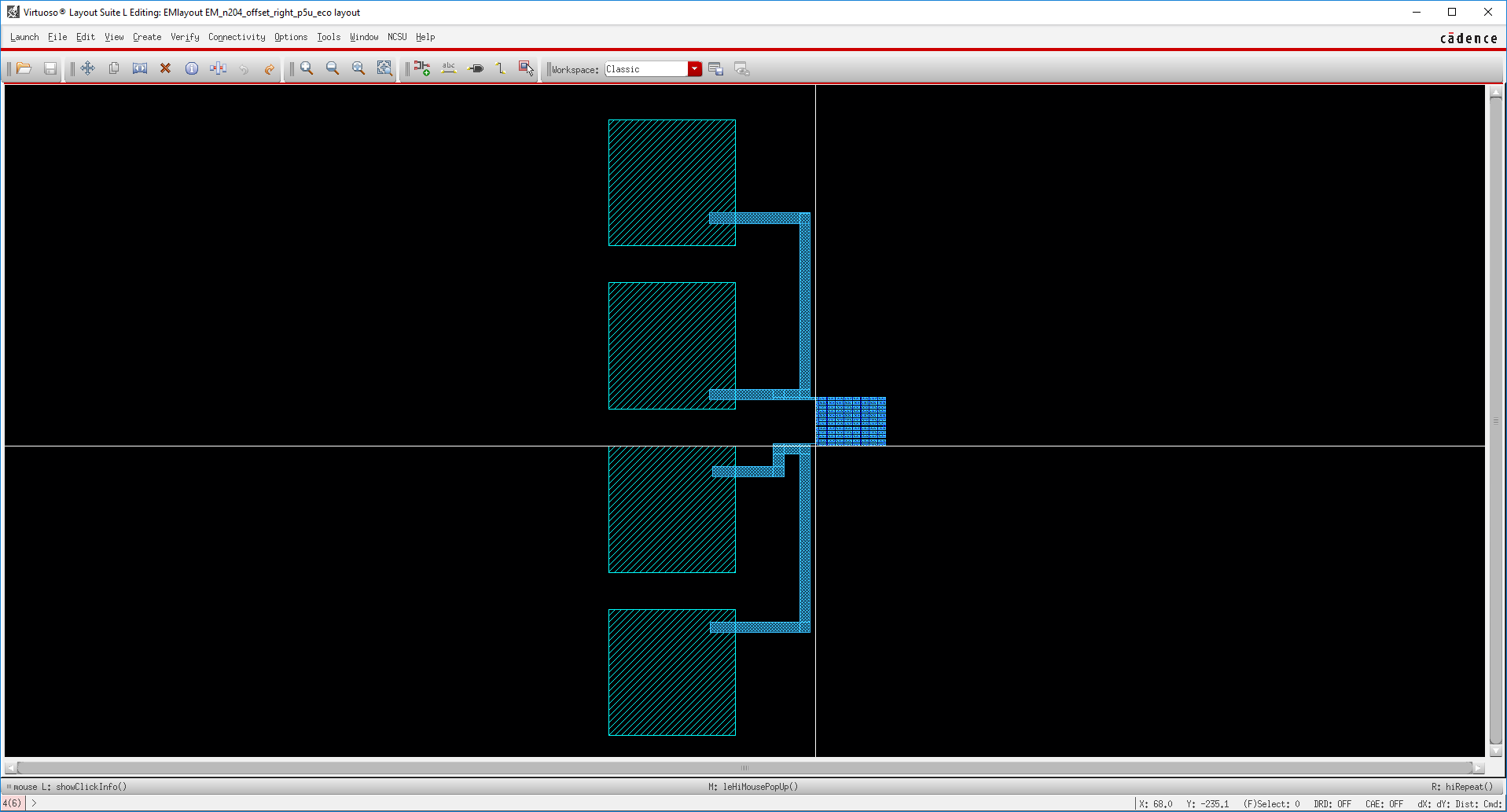

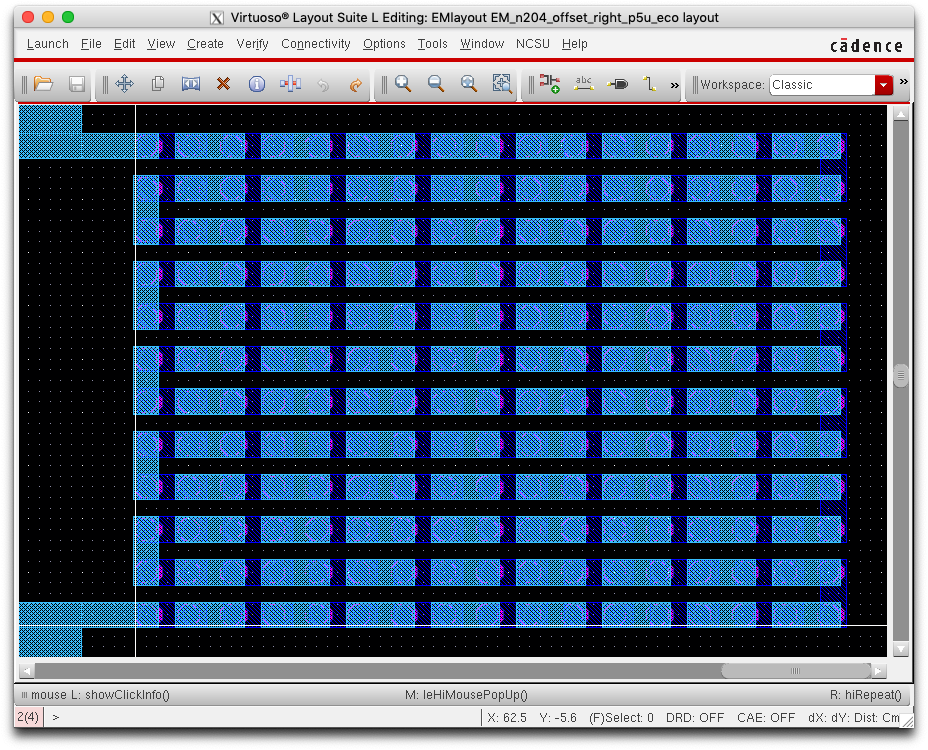

Virtuoso® Layout Suite L Editing: EMlayout EM_n204_offset_right_p5u_eco

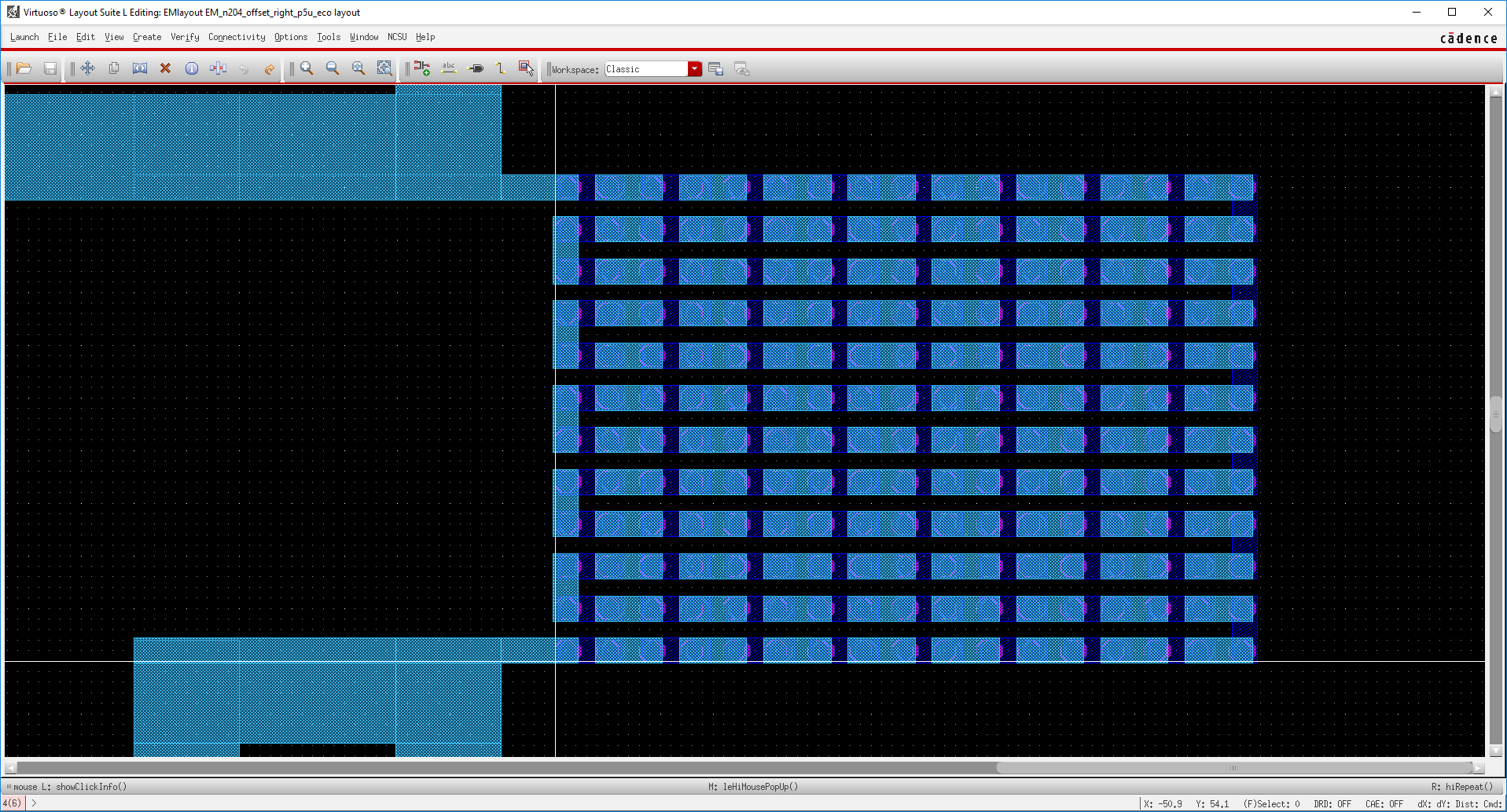

Zoom in to review the 204-via in chain geometry

Layout MOSIS IC Layer Information

https://www.eda.ncsu.edu/wiki/MOSIS_Layers

Test pad size: 120um x 120 um. Pitch: 250um, which means 130um spacing between 2 test pads.  With maligned vias, or different numbers of links, or different trace widths. Make the layouts for offset (+x positive is right). Submitted GDSII to Novati Technologies, Inc. For Harris Corporation and ICAMR.

With maligned vias, or different numbers of links, or different trace widths. Make the layouts for offset (+x positive is right). Submitted GDSII to Novati Technologies, Inc. For Harris Corporation and ICAMR.

- Bottom wafer layers are M1 and DB1; top wafer (thinned) are M2 and DB2.

- DBI1/DBI2 thicknesses is 1.5 um. M1/M2 thicknesses is 1 um.

- DBI is about 3.14/16 ~ 20%. M1 and M2 is ~2.4/4 = 60% on interior of via chains and combs.

- Here is how the layers in GDS files corresponding to layers in the test vehicle.

Summary of EM Structures

Macintosh User

Comments

So empty here ... leave a comment!