My sincerest apologies for the terrible pun. They will only get worse as the weekend progresses. We have arrived! The weather was excellent for flying both legs of the journey, and we have confirmed that our plane arrived to Wichita intact. This is crucial, because having a plane is integral to participating in an airplane competition.*

*Citation needed.

We experienced some minor turbulence en route, and in keeping with our new educational theme, I would like to explain that phenomenon.

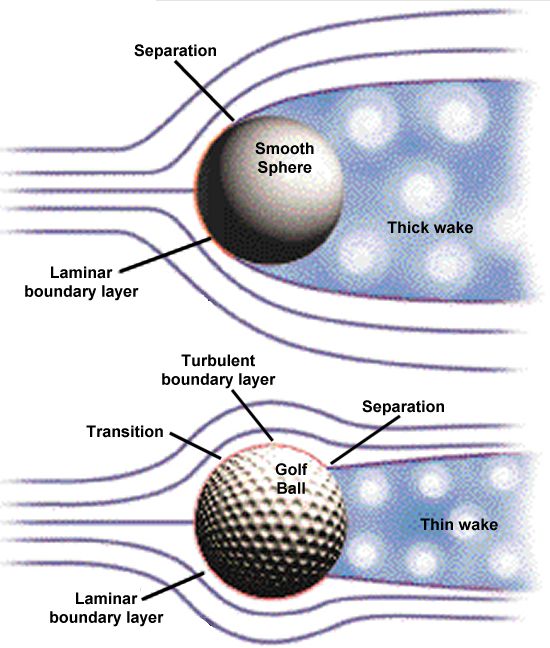

In general, turbulent flow is the motion of a fluid (air, water, or whatever) that is chaotic and unpredictable. Pressure and velocity are highly variable within turbulent areas. Turbulence is, to simplify things, caused when the oncoming flow is moving fast enough that it scatters and disperses from its original, laminar pattern.

Not everyone knows it, but the external flow around airplanes is actually already turbulent! Laminar flow is “tripped” into turbulence by the plane slicing through the air. This is actually a good thing, because turbulent flow “tumbles” along the wing for a greater distance before separating. Picture a large semi truck, and the lull of air behind it. There is a high pressure in the front of the truck (oncoming air) but very low pressure directly behind it, because all of the air has been forced out of the way. For an airplane, the boundary layer separating from the wing can be a major source of drag. Minimizing this pressure drag effect is important, and so turbulent flow is useful for planes, cars, and so on. This is good, because at high speeds and for large objects, turbulence is unavoidable!

Designers will even go out of their way to induce turbulence! Golf balls are a clear example. A smooth sphere the size of a golf ball, hit by a human golfer, will not cause turbulent flow and hence the boundary layer will slip off quite early. (Clark Kent might be able to induce turbulent flow with a golf swing, but he can also fly backwards around the Earth to turn back time if he wants.) A rougher surface, like a golf ball with dimples, induces turbulent flow and a boundary layer that does not separate as early, greatly reducing pressure drag.

Designers will even go out of their way to induce turbulence! Golf balls are a clear example. A smooth sphere the size of a golf ball, hit by a human golfer, will not cause turbulent flow and hence the boundary layer will slip off quite early. (Clark Kent might be able to induce turbulent flow with a golf swing, but he can also fly backwards around the Earth to turn back time if he wants.) A rougher surface, like a golf ball with dimples, induces turbulent flow and a boundary layer that does not separate as early, greatly reducing pressure drag.